The Basics of Bearings Imagine world

The Basics of Bearings Imagine world

Blog Article

Imagine a world where machines grind to a halt because of a tiny, often overlooked component. Bearings, though small, play a crucial role in the functionality of countless machines, from cars to industrial equipment. Understanding the Essential bearing facts can make a significant difference in performance and longevity. Let's delve into what makes bearings vital and how to choose the right type for your needs.

The Basics of Bearings

Bearings are mechanical components that allow for smooth rotation or linear movement between parts. Their primary function is to reduce friction between moving parts, which can lead to wear and tear over time. Without bearings, machinery would not operate efficiently, leading to increased energy costs and frequent breakdowns.

Types of Bearings

There are various types of bearings, each designed for specific applications. The most common include:

- Ball Bearings: These are versatile and widely used in everything from bicycles to household appliances. They can handle both radial and axial loads.

- Roller Bearings: Ideal for heavy loads, they provide a larger contact area than ball bearings, making them suitable for industrial applications.

- Tapered Roller Bearings: These bearings can handle both radial and axial loads. They're commonly used in automotive applications, such as in wheel hubs.

- Spherical Roller Bearings: Designed to accommodate misalignment, these bearings are often used in heavy machinery.

Choosing the Right Bearing

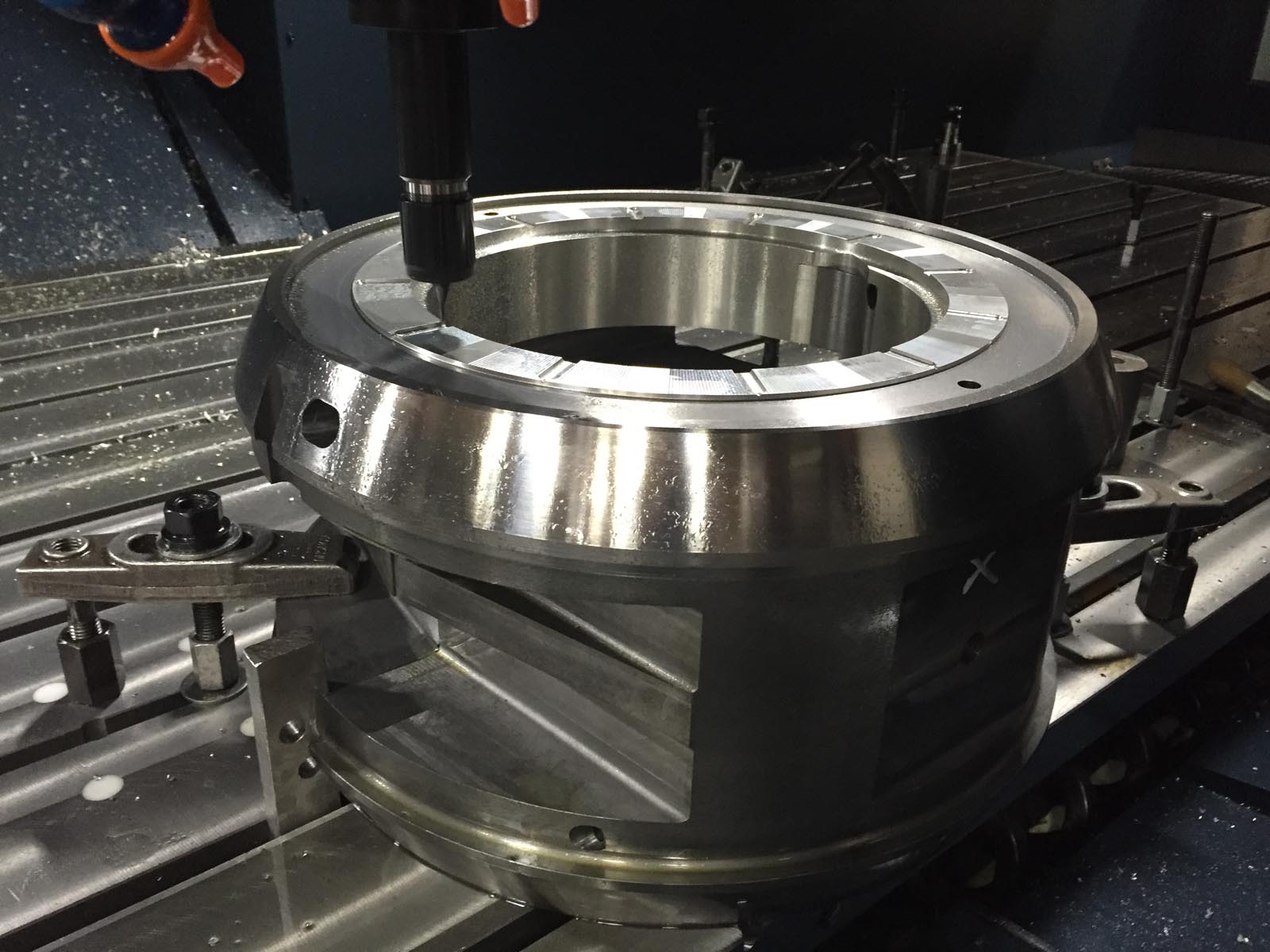

Selecting the proper bearing for your application involves several considerations. First, it’s essential to assess the load requirements. Bearings can be subjected to different types of loads, including radial, axial, or a combination of both. Understanding the load type will guide you in selecting the right bearing type.

[IMAGE]

Next, consider the environmental conditions in which the bearing will operate. Factors such as temperature, humidity, and exposure to contaminants can affect bearing performance. For instance, stainless steel bearings are preferable in corrosive environments, while sealed bearings can prevent the ingress of dirt and moisture.

Maintenance Matters

Proper maintenance is key to extending the lifespan of bearings. Regular inspections can help identify signs of wear, such as noise or unusual vibrations. Lubrication is also vital; it reduces friction and prevents overheating. Depending on the type of bearing, lubrication methods can vary—from grease packs to oil baths. Neglecting maintenance can lead to catastrophic failures, resulting in costly downtime.

Innovations in Bearing Technology

As industries evolve, so too does bearing technology. Recent advancements have led to the development of hybrid bearings, which combine ceramic balls with steel rings. These bearings offer improved performance, reduced friction, and greater resistance to wear and corrosion. Additionally, smart bearings equipped with sensors can monitor their condition in real-time, providing valuable data for predictive maintenance.

Conclusion

Understanding the Essential bearing facts can empower you to make informed decisions that enhance machinery performance and longevity. By selecting the right type of bearing and committing to regular maintenance, you can ensure that your equipment operates smoothly and efficiently. The next time you think about the intricate workings of machinery, remember the vital role bearings play in keeping everything moving.

Report this page