The Significance of Testing in Brush Machine Production

The Significance of Testing in Brush Machine Production

Blog Article

In the rapidly evolving landscape of manufacturing, the importance of rigorous testing in production processes cannot be overstated. Each component of machinery, especially in specialized sectors like brush machine production, requires comprehensive evaluation to ensure optimal performance, safety, and durability. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., a leader in this field with 37 years of experience, exemplifies the commitment to quality through meticulous testing methods.

At Jiangmen Meixin, the focus on producing advanced 2-5 axis machines goes beyond mere assembly; it hinges on a deep-rooted philosophy of quality assurance. This dedication ensures that every machine that leaves the factory meets stringent industry standards and is equipped to handle the demands of modern production environments. Understanding the significance of testing not only enhances product reliability but also fortifies the company’s reputation as a trusted manufacturer in the brush machine sector.

Overview of Brush Machine Production

The production of brush machines is a critical aspect of the manufacturing industry, particularly in the creation of various types of brushes used in different applications. These machines play a vital role in ensuring that the brushes are made efficiently and to a high standard. In a competitive market, the ability to produce quality brushes quickly and reliably can be a determining factor for success.

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has established itself as a leader in this field, specializing in the production of 2-5 axis machines. With 37 years of experience, the company has honed its technical expertise and accumulated valuable knowledge in the brush-making process. This long-standing presence in the industry has enabled the company to innovate and improve upon existing technologies, ensuring that their machinery meets the evolving demands of the market.

The significance of testing in brush machine production cannot be overstated. Rigorous testing protocols are essential to ensure that each machine operates efficiently and produces high-quality brushes. Testing not only helps in identifying design flaws but also validates the performance of the machines under various conditions, ultimately enhancing reliability and customer satisfaction. As manufacturers strive for operational excellence, effective testing methodologies become integral to the production workflow.

Importance of Quality Testing

Quality testing is a critical component in the production process of brush machines. For a company like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., with over 37 years of experience, ensuring the durability and efficiency of their 2-5 axis machines is paramount. Rigorous quality testing allows manufacturers to identify potential defects and ensure that the machines meet industry standards, which is essential for maintaining a competitive edge in the market.

The benefits of a well-established quality testing protocol extend beyond just meeting regulations. Consistent testing allows for the optimization of production processes and helps in the early detection of any issues that might arise during manufacturing. This proactive approach not only saves time and resources but also enhances customer satisfaction by delivering reliable products. When clients trust the quality of the machines provided, it builds a solid reputation that can lead to repeat business and positive referrals.

Moreover, quality testing fosters continuous improvement within the manufacturing process. By analyzing the results of various tests, Jiangmen Meixin can continually refine their machinery and production methodologies. This iterative process helps in innovation and adapting to evolving market needs, ensuring that the company remains at the forefront of brush machine technology. The significance of quality testing cannot be underestimated, as it is fundamental to the success and sustainability of brush machine production.

Technological Innovations at Jiangmen Meixin

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. has established itself as a leader in the brush machine production industry through its commitment to technological innovation. With over 37 years of experience, the company has continuously adapted and improved its manufacturing processes by integrating advanced technologies. This dedication allows them to produce high-performance 2-5 axis machines that meet the evolving demands of their customers.

One of the key innovations at Jiangmen Meixin is the implementation of smart automation in their manufacturing lines. By using industry 4.0 principles, the company has improved efficiency while reducing operational costs. Automated systems are employed for quality control and real-time monitoring, ensuring that every machine produced meets the highest standards. This integration of technology streamlines production and enhances product reliability, a crucial factor for customers in the competitive brush market.

Furthermore, Jiangmen Meixin invests heavily in research and development to stay ahead of industry trends. Their skilled team of engineers and technicians regularly collaborates to develop new machine features and refine existing ones. This proactive approach has led to significant advancements in machine ergonomics and user interface design, making it easier for operators to use their machines effectively. The result is not only a better end product but also improved customer satisfaction and loyalty.

Production Process and Testing Methods

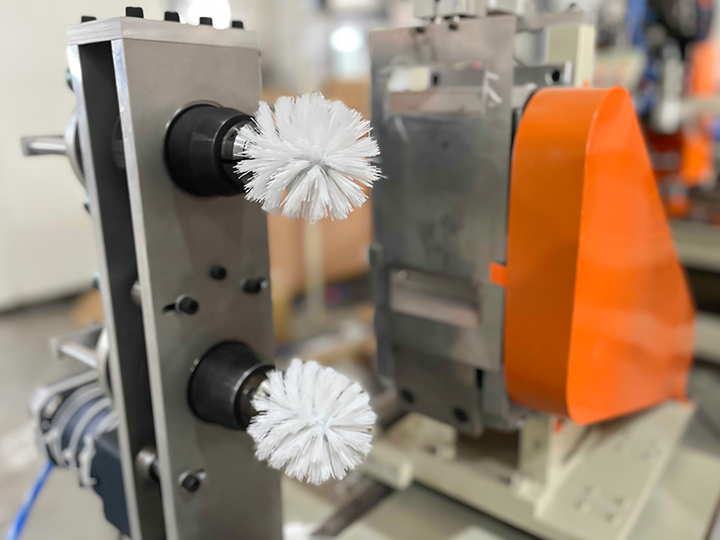

Industrial Brush Making Equipment

The production of brush machines at Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. involves a highly systematic approach that integrates advanced technology with meticulous craftsmanship. The process begins with sourcing high-quality materials necessary for durability and performance. Skilled technicians utilize state-of-the-art 2-5 axis machines, leveraging 37 years of accumulated expertise to ensure precision in every component manufactured.

To maintain the highest standards, rigorous testing methods are employed at various stages of production. Each machine part undergoes thorough inspection to assess dimensions, strength, and functionality. The testing procedures include both manual and automated checks, focusing on aspects such as motor efficiency, operational speed, and overall assembly integrity. This commitment to quality assurance is crucial for the reliability and longevity of the machines produced.

After final assembly, the brush machines are subjected to a comprehensive quality control process before leaving the factory. This includes performance testing under real-world conditions to guarantee that each machine meets industry standards and customer expectations. By implementing these stringent testing protocols, Jiangmen Meixin ensures that their machines not only meet but exceed customer demands, solidifying their reputation as a leader in brush machine production.

Conclusion and Future Perspectives

The significance of rigorous testing in brush machine production cannot be overstated. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. exemplify the importance of a strong quality assurance process, backed by over 37 years of experience. Their commitment to delivering high-quality 2-5 axis machines reflects a thorough understanding of both industry standards and customer expectations. By incorporating advanced testing methods, the company ensures that each machine performs optimally, reducing the likelihood of defects and complaints.

Looking ahead, the brush machine industry is poised for significant advancements, particularly in automation and smart manufacturing technologies. As Jiangmen Meixin continues to innovate, the integration of AI and IoT in testing processes will likely enhance efficiency and accuracy. These technologies can facilitate real-time monitoring and preventive maintenance, further solidifying the company’s position as a leader in the market. The evolution of testing protocols will play a crucial role in adapting to changing demands and maintaining high production standards.

Moving forward, industry players must prioritize not only the technical aspects of machine design but also the holistic approach to quality control. Collaboration with suppliers, continuous training for personnel, and investment in cutting-edge equipment will be vital. For Jiangmen Meixin, embracing these future trends will not only sustain their legacy but will also pave the way for new opportunities in an increasingly competitive landscape. The dedication to testing and quality will ensure that they remain a prominent force in brush machine production.

Report this page